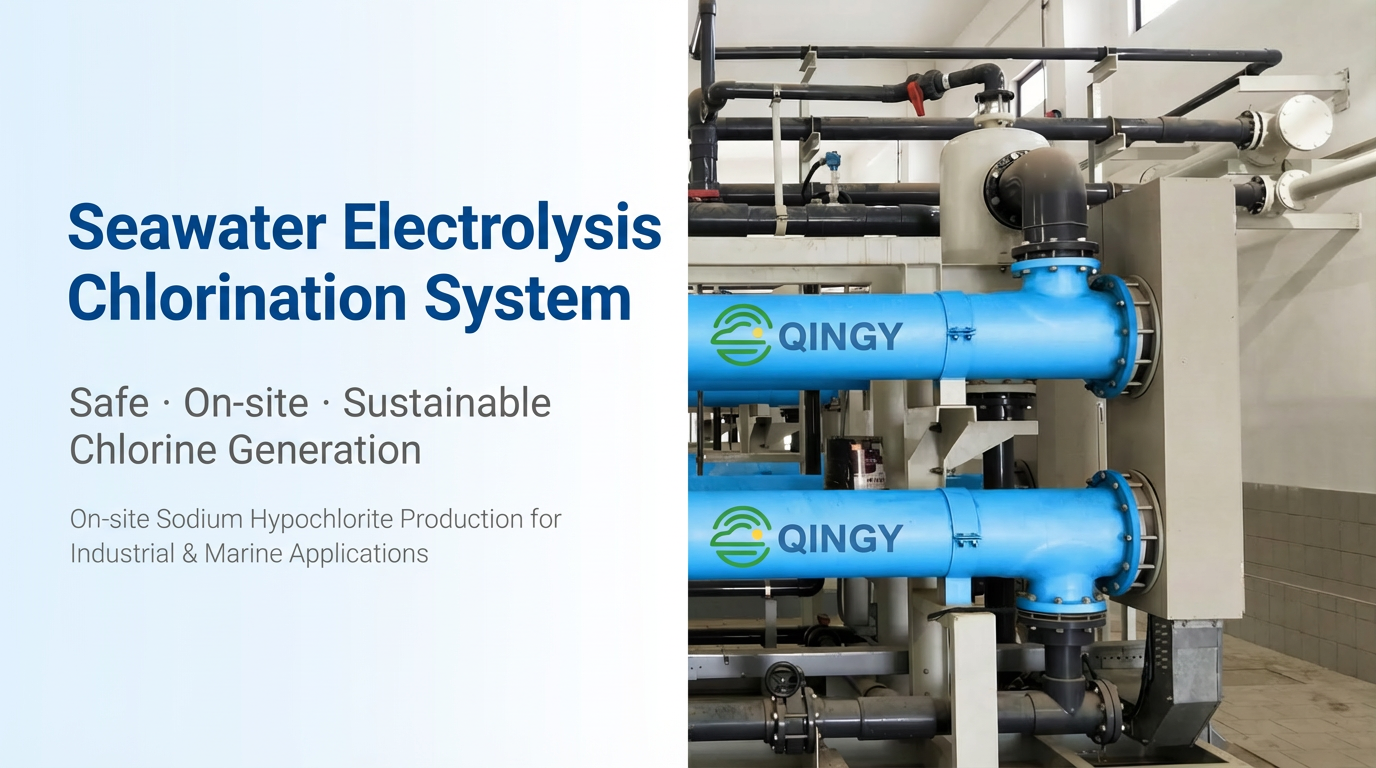

In the power generation industry, maintaining efficient and reliable water treatment systems is critical for both operational performance and environmental compliance. The QINGY Seawater Electrolysis Chlorination System has emerged as a game-changing technology for coastal power plants, providing an efficient, cost-effective solution for producing on-demand chlorine that addresses the unique requirements of power generation operations.

Power plants, particularly those located near coastal areas, rely on water treatment systems for multiple essential functions:

– **Cooling water disinfection** to prevent biofouling in condenser tubes and cooling systems

– **Wastewater treatment** to meet environmental discharge regulations

– **Boiler water treatment** for maintaining steam generation efficiency

– **Desalination processes** for plants utilizing seawater for freshwater production

– **Fire protection systems** to ensure water quality in emergency systems

Traditional chemical treatment methods involving hazardous chlorine gas or pre-fabricated chlorine solutions have proven problematic for power plants due to safety concerns, transportation costs, and regulatory compliance issues.

The QINGY Seawater Electrolysis Chlorination System addresses the power industry’s specific requirements through innovative design features:

– **Direct seawater utilization** eliminating the need for brine preparation or chemical handling

– **High-efficiency electrolysis technology** producing chlorine with minimal energy consumption

– **Compact footprint** maximizing space efficiency in power plant environments

– **Automated operation** with advanced control systems that integrate with plant monitoring networks

– **Modular design** allowing flexible installation and expansion as facility needs evolve

The system produces sodium hypochlorite by electrolyzing seawater directly, offering a more cost-effective and environmentally friendly solution compared to other chlorination methods while maintaining the high disinfection efficiency required for power plant applications.

QINGY Seawater Electrolysis Systems serve multiple critical functions across power generation operations:

- **Condenser biofouling control** – Preventing marine organism growth in cooling water systems that can reduce heat transfer efficiency

- **Circulating water treatment** – Maintaining water quality in closed-loop cooling systems

- **Wastewater disinfection** – Ensuring compliance with environmental regulations for discharge water

- **Reverse osmosis pre-treatment** – Controlling biological growth in desalination processes

- **Ballast water treatment** – For power plants with their own shipping operations

- **Potable water treatment** – Providing safe drinking water for plant personnel

The versatility of the QINGY system allows it to adapt to different water sources and treatment requirements throughout power plant operations.

Compared to conventional chlorine gas or pre-packaged chemical solutions, the QINGY system offers significant advantages for power plants:

– **Enhanced safety** by eliminating the risks associated with storing and handling dangerous chemicals

– **Cost efficiency** through on-site production that avoids transportation and storage costs

– **Consistent quality** of fresh sodium hypochlorite without degradation issues

– **Environmental benefits** through reduced carbon footprint from transportation elimination

– **Regulatory compliance** with strict environmental protection standards

The generator’s ability to produce sodium hypochlorite at adjustable concentrations ensures optimal disinfection performance while minimizing corrosion concerns in sensitive power plant equipment.

QINGY chlorination systems are designed to meet the rigorous demands of power plant environments through:

– **Corrosion-resistant materials** throughout the system including marine-grade stainless steel components

– **Redundant systems** to ensure continuous operation even during partial equipment failure

– **Minimal maintenance requirements** with self-cleaning electrodes and automated monitoring

– **Integration capabilities** with existing plant control and monitoring systems

– **Customizable production capacity** to match specific facility requirements

These features make the QINGY system particularly suitable for the demanding operational requirements of power plants where downtime can be extremely costly.

As power plants continue to adopt more sustainable practices and face increasing environmental regulations, the demand for reliable, efficient water treatment solutions will only increase. The QINGY Seawater Electrolysis Chlorination System represents the next generation of water treatment technology for power generation applications, combining advanced engineering with practical design to meet the evolving needs of the power industry.

By choosing QINGY, power plant operators benefit from a system that not only meets current regulatory requirements but also provides a scalable solution that can adapt to future challenges. The technology’s proven reliability in power generation environments has established it as the preferred choice for forward-thinking power companies seeking to optimize their water treatment processes while maintaining the highest safety and environmental standards.

For power plant operators looking to upgrade their water treatment capabilities, the QINGY Seawater Electrolysis Chlorination System offers a comprehensive solution that addresses both current needs and future requirements in this critical industry sector.