In the fast-paced world of electronics manufacturing, where precision, purity, and sustainability are paramount, hydrogen has emerged as a critical enabler for cutting-edge production processes. The QINGY Alkaline Water Electrolysis Hydrogen System has established itself as an indispensable technology in this sector, providing a reliable, high-purity hydrogen supply that addresses the unique requirements of semiconductor, display, and electronic component manufacturing.

The electronics industry relies on hydrogen for numerous critical applications that demand exceptional purity levels:

– **Semiconductor manufacturing** requires ultra-high purity hydrogen (99.9999%+) for wafer cleaning, surface treatment, and as a reducing agent in deposition processes

– **Flat panel display production** uses hydrogen for annealing, surface activation, and as a carrier gas in various coating processes

– **Solar cell manufacturing** depends on hydrogen for anti-reflective coating and passivation treatments

– **Battery production** for electric vehicles and consumer electronics utilizes hydrogen in electrode manufacturing processes

– **LED and optoelectronics manufacturing** requires hydrogen for epitaxial growth and surface treatment

As electronic devices become smaller, more powerful, and more complex, the demand for high-purity hydrogen continues to grow exponentially, with even minor impurities potentially causing costly production defects.

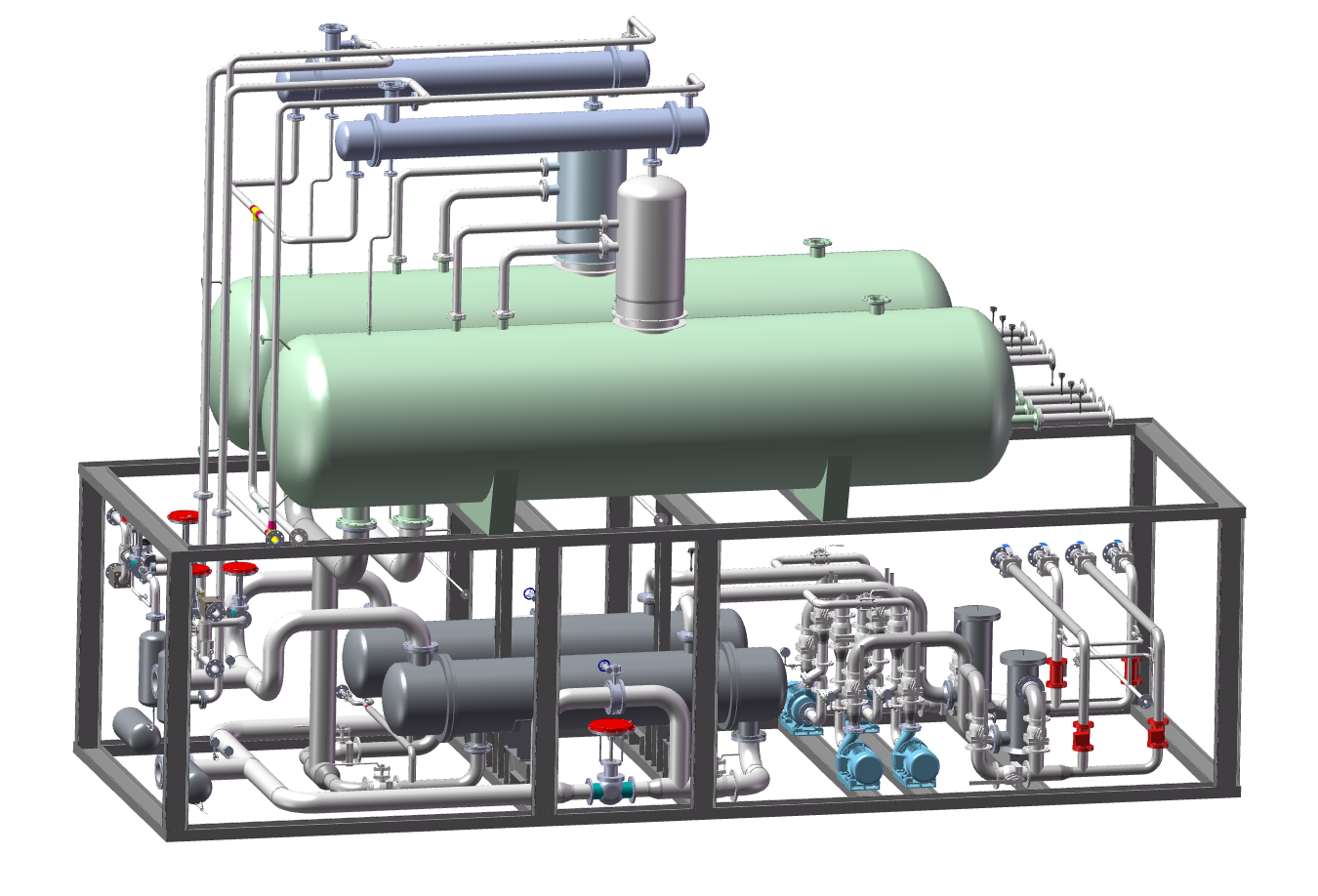

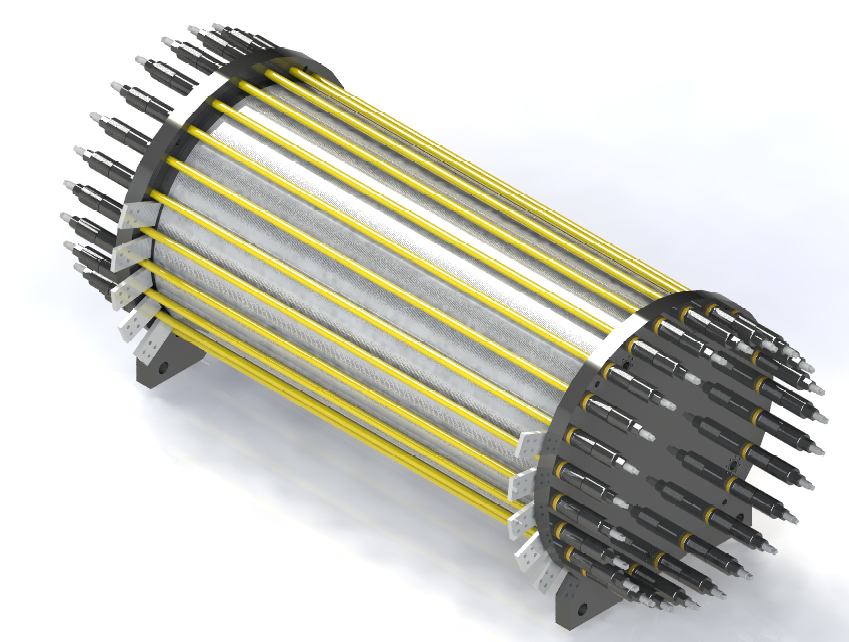

The QINGY Alkaline Water Electrolysis Hydrogen System addresses the electronics industry’s specific requirements through innovative design features:

– **Exceptional purity levels** producing hydrogen with up to 99.9999% purity, meeting the most stringent electronics industry standards

– **Scalable production capacity** ranging from small laboratory-scale systems to large industrial installations

– **Stable, consistent output** ensuring uninterrupted hydrogen supply critical for continuous manufacturing processes

– **Modular design** allowing flexible installation and expansion as production needs evolve

– **Energy-efficient operation** reducing the carbon footprint of electronics manufacturing while lowering operational costs

The system produces hydrogen through the electrolysis of water using potassium hydroxide (KOH) as the electrolyte, offering a more cost-effective solution compared to other hydrogen production methods while maintaining the high purity required for electronics applications.

QINGY Alkaline Water Electrolysis Systems serve multiple critical functions across electronics production:

- **Wafer cleaning and surface treatment** – Removing organic and inorganic contaminants from silicon wafers before processing

- **Atmosphere control** – Maintaining precise hydrogen concentrations in controlled environments for deposition processes

- **Annealing processes** – Improving material properties through controlled heating in hydrogen atmospheres

- **Carrier gas applications** – Serving as a high-purity carrier gas for chemical vapor deposition (CVD) and other processes

- **Reduction reactions** – Acting as a reducing agent in various material synthesis processes

- **Cooling applications** – Providing efficient cooling in high-temperature manufacturing equipment

The versatility of the QINGY system allows it to adapt to the diverse hydrogen requirements across different stages of electronics production.

Compared to traditional hydrogen supply methods like cylinder delivery or other production technologies, the QINGY system offers significant advantages:

– **Cost efficiency** through on-site production that eliminates transportation costs and cylinder rental fees

– **Consistent purity** avoiding contamination risks associated with cylinder changes and transportation

– **Supply reliability** ensuring uninterrupted hydrogen access without dependence on external suppliers

– **Safety benefits** through integrated safety systems and reduced handling of high-pressure cylinders

– **Environmental sustainability** producing hydrogen from water with minimal carbon footprint when powered by renewable energy

The system’s ability to produce hydrogen with adjustable purity levels makes it suitable for both high-purity applications like semiconductor manufacturing and lower-purity requirements in other production stages.

QINGY hydrogen systems are designed to meet the rigorous demands of electronics manufacturing through:

– **Advanced purification technologies** including pressure swing adsorption (PSA) and membrane separation for achieving ultra-high purity levels

– **Automated operation** with real-time monitoring of key parameters including purity, pressure, and flow rate

– **Integration capabilities** with existing production control systems for seamless process integration

– **Remote monitoring and diagnostics** allowing proactive maintenance and minimizing downtime

– **Compliance with industry standards** including SEMI (Semiconductor Equipment and Materials International) specifications

These features make the QINGY system particularly suitable for the demanding operational requirements of electronics manufacturing where even minor interruptions can lead to significant production losses.

As the electronics industry continues to innovate with smaller, more complex components, the demand for reliable, high-purity hydrogen will only increase. The QINGY Alkaline Water Electrolysis Hydrogen System represents the next generation of hydrogen production technology for electronics applications, combining advanced engineering with practical design to meet the evolving needs of this dynamic industry.

By choosing QINGY, electronics manufacturers benefit from a system that not only meets current production requirements but also provides a scalable solution that can adapt to future technological advancements. The technology’s proven reliability in demanding manufacturing environments has established it as the preferred choice for forward-thinking electronics companies seeking to optimize their production processes while maintaining the highest quality standards.

For electronics manufacturers looking to upgrade their hydrogen supply capabilities, the QINGY Alkaline Water Electrolysis Hydrogen System offers a comprehensive solution that addresses both current needs and future requirements in this rapidly evolving industry.