The global metallurgical industry is undergoing a profound transformation as companies seek to reduce carbon emissions while maintaining operational efficiency. In this context, alkaline electrolysis hydrogen equipment has emerged as a game-changer, offering a sustainable solution to meet the industry’s growing hydrogen demands.

Metallurgy, particularly steelmaking, has long been one of the world’s most carbon-intensive industries. Traditional processes rely heavily on coal and coke, contributing significantly to greenhouse gas emissions. The adoption of hydrogen as a clean energy carrier represents a paradigm shift, enabling metal producers to decarbonize their operations while maintaining product quality.

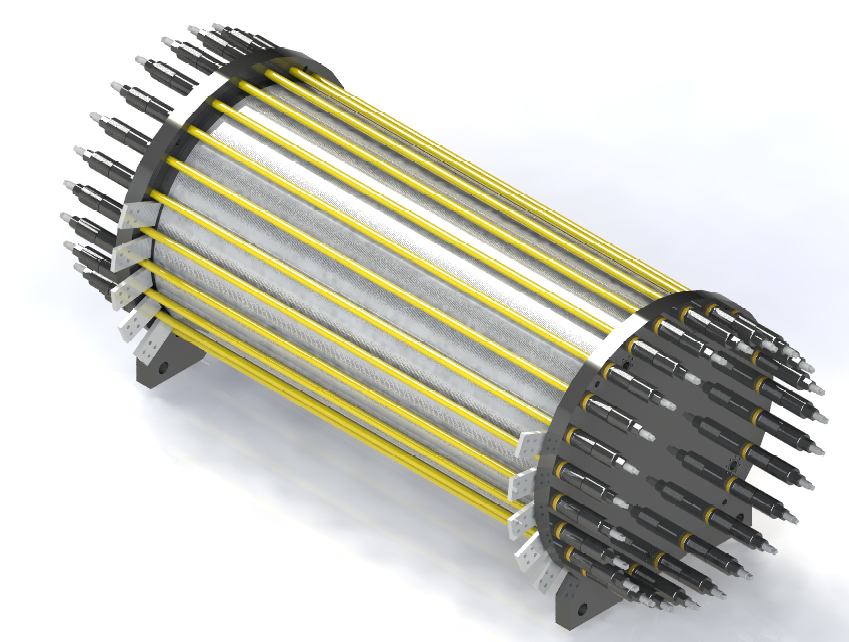

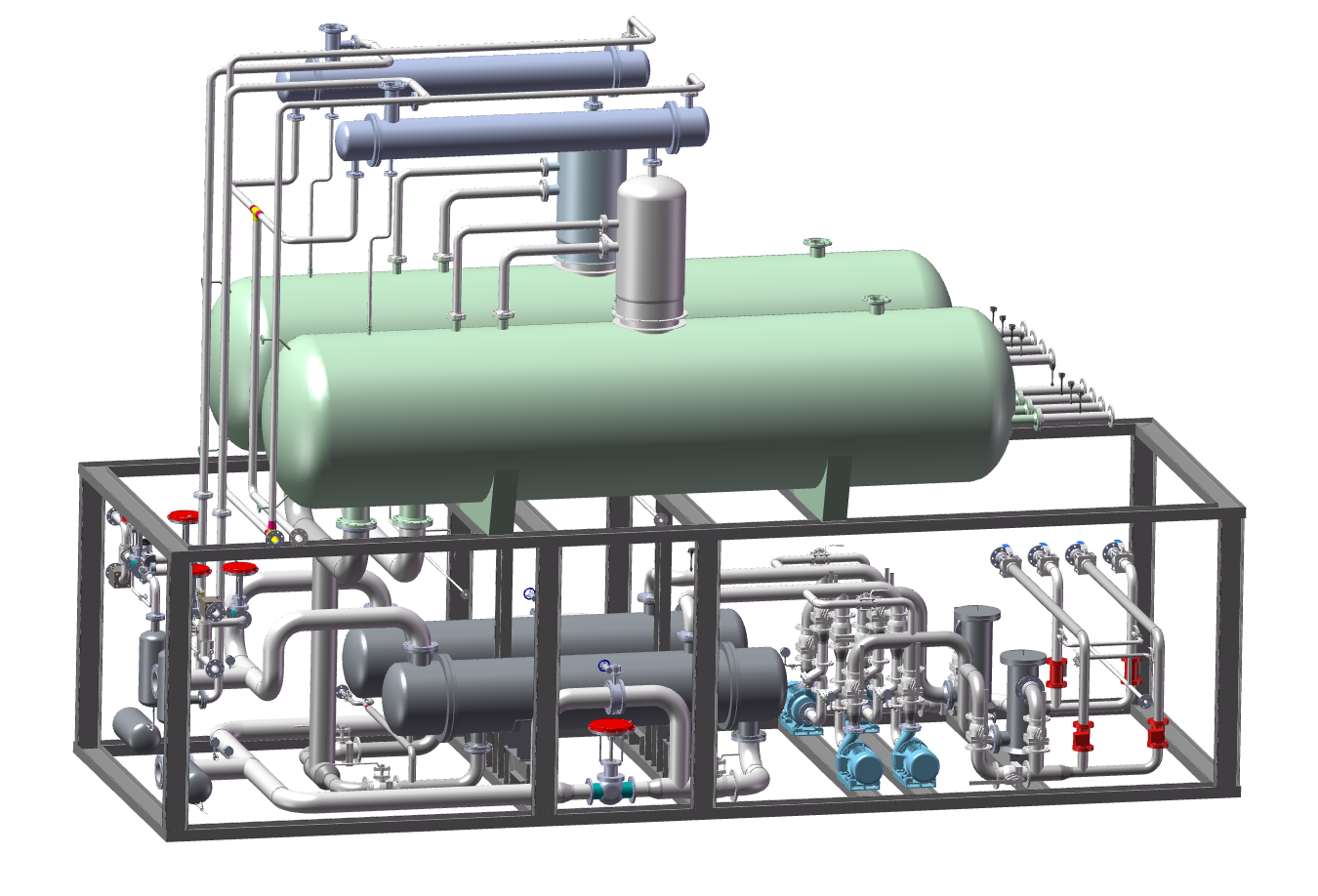

QINGY alkaline electrolysis hydrogen equipment provides a reliable, cost-effective method for on-site hydrogen production, addressing the unique challenges faced by metallurgical facilities. The ability to generate hydrogen directly at the point of use eliminates transportation costs and ensures a consistent supply, even during peak production periods.

The versatility of hydrogen in metallurgical applications is remarkable, with QINGY alkaline electrolyzers supporting several critical processes:

- **Direct Reduction of Iron Ore**

– Hydrogen replaces carbon monoxide as the reducing agent in iron ore reduction

– Produces high-quality direct reduced iron (DRI) with minimal carbon footprint

– Enables the creation of “green steel” with significantly lower embodied carbon

- **Annealing and Heat Treatment**

– Hydrogen provides an inert atmosphere for metal annealing processes

– Prevents oxidation and surface discoloration during heat treatment

– Improves final product quality and reduces material waste

- **Metal Refining and Purification**

– Hydrogen serves as a powerful reducing agent in various metal refining processes

– Effective for removing oxides and other impurities from metals

– Particularly valuable in aluminum, copper, and precious metal refining

QINGY alkaline electrolysis hydrogen equipment offers distinct advantages that make it particularly well-suited for metallurgical environments:

– **High Purity Output**: Produces hydrogen with purity levels exceeding 99.999%, meeting the stringent requirements of sensitive metallurgical processes

– **Operational Flexibility**: Can adjust production levels to match fluctuating demand patterns common in batch metallurgical operations

– **Robust Design**: Engineered to withstand the harsh conditions often found in metallurgical facilities

– **Scalability**: Systems can be modularly expanded to accommodate growing hydrogen needs as production scales up

– **Low Maintenance Requirements**: Designed for continuous operation with minimal downtime, critical for maintaining production schedules

The metallurgical industry’s hydrogen needs are unique, requiring equipment that can deliver consistent performance under demanding conditions. QINGY alkaline electrolysis systems address these specific requirements through:

– **High Pressure Capability**: Systems can produce hydrogen at pressures up to 30 bar, suitable for direct integration into existing pipeline infrastructure

– **Customizable Solutions**: Tailored configurations to match specific production capacities and space constraints

– **Rapid Response Time**: Ability to adjust production in response to process demands, ensuring optimal resource utilization

– **Energy Efficiency**: Advanced cell design minimizes energy consumption, reducing operational costs

– **Safety Features**: Comprehensive safety systems engineered specifically for industrial environments

Beyond environmental benefits, QINGY alkaline electrolysis hydrogen equipment delivers compelling economic advantages:

– **Cost Stability**: On-site production reduces exposure to volatile hydrogen market prices

– **Energy Cost Optimization**: Can leverage off-peak electricity rates for hydrogen production, lowering overall energy expenses

– **Government Incentives**: Eligible for various carbon reduction and clean energy incentives in many regions

– **Future-Proofing**: Prepares operations for upcoming carbon pricing mechanisms and regulatory requirements

– **Brand Enhancement**: Demonstrates commitment to sustainability, improving market positioning and customer appeal

As the metallurgical industry transitions toward carbon neutrality, alkaline electrolysis hydrogen equipment has become more than just a technological innovation—it’s a strategic necessity. QINGY systems empower metal producers to reduce their environmental impact while maintaining competitiveness in an increasingly sustainability-focused market.

By integrating our alkaline electrolysis hydrogen equipment into your metallurgical operations, you’re not just investing in a piece of machinery—you’re investing in a sustainable future for your company and the industry as a whole. Contact us today to discover how our tailored solutions can help your metallurgical facility achieve its decarbonization goals while enhancing operational efficiency and profitability.

The future of metallurgy is hydrogen-powered, and QINGY alkaline electrolysis equipment is leading the way toward this transformative shift.