As the world accelerates its transition to sustainable energy, renewable hydrogen has emerged as the critical bridge between intermittent renewable generation and reliable energy supply. QINGY’s alkaline electrolysis water-to-hydrogen equipment stands at the forefront of this transformation, enabling efficient capture, storage, and utilization of renewable energy across sectors.

Renewable energy sources like solar and wind are inherently variable—their output fluctuates with weather conditions and time of day. This intermittency creates a fundamental mismatch between energy supply and demand, often forcing grid operators to curtail excess renewable energy or rely on fossil fuel backups. Hydrogen solves this problem by acting as a versatile energy carrier: excess renewable electricity powers electrolysis to produce hydrogen, which is then stored for later use when renewable generation is low.

QINGY alkaline electrolysis systems are specifically engineered to address this challenge, providing a reliable, efficient means to convert surplus renewable energy into storable hydrogen. This “power-to-gas” approach transforms renewable energy into a dispatchable resource, effectively turning seasonal surpluses into year-round energy security.

QINGY alkaline electrolysis technology offers distinct advantages that make it particularly well-suited for renewable energy integration:

– **Dynamic Load Following**: Our systems excel at handling the variable output of solar and wind farms, adjusting hydrogen production in real-time to match fluctuations in renewable generation

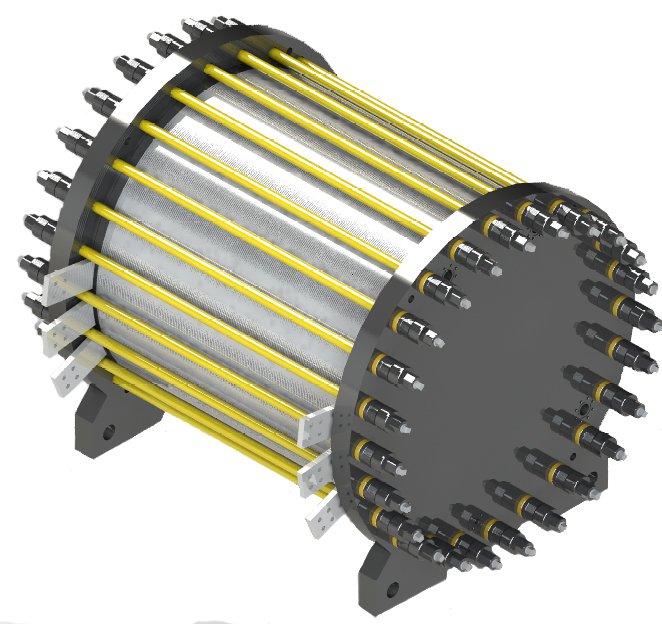

– **High Efficiency**: Advanced cell design and optimized operating parameters ensure maximum conversion of electricity to hydrogen, even at partial load conditions

– **Rapid Response**: Capable of starting up and ramping production within minutes, critical for capturing short-term renewable energy surpluses

– **Scalability**: Modular design allows systems to grow alongside renewable energy installations, from small distributed projects to utility-scale facilities

– **Durability**: Robust construction ensures reliable operation in remote locations often associated with large renewable energy projects

QINGY alkaline electrolysis equipment supports several key applications in renewable hydrogen production:

- **Grid Balancing and Energy Arbitrage**

Our systems capture excess renewable energy during periods of high generation (e.g., midday solar peaks) and convert it to hydrogen, which is stored for use during peak demand periods. This arbitrage strategy maximizes the value of renewable energy assets while stabilizing grid operations.

- **Offshore Wind-to-Hydrogen**

QINGY compact, corrosion-resistant systems are ideal for integration with offshore wind farms, producing hydrogen directly at sea. This eliminates the need for costly undersea electricity cables, turning offshore wind into a source of storable, transportable energy.

- **Solar-to-Hydrogen**

In sun-drenched regions, our electrolyzers pair with large-scale solar installations to produce hydrogen during daylight hours. The stored hydrogen can then be used for nighttime power generation or transported to energy-deficient areas.

- **Remote Area Power Supply**

For isolated communities or industrial sites, QINGY systems create self-sufficient energy loops: renewable generation powers electrolysis, hydrogen is stored, and fuel cells convert it back to electricity when needed, eliminating reliance on diesel generators.

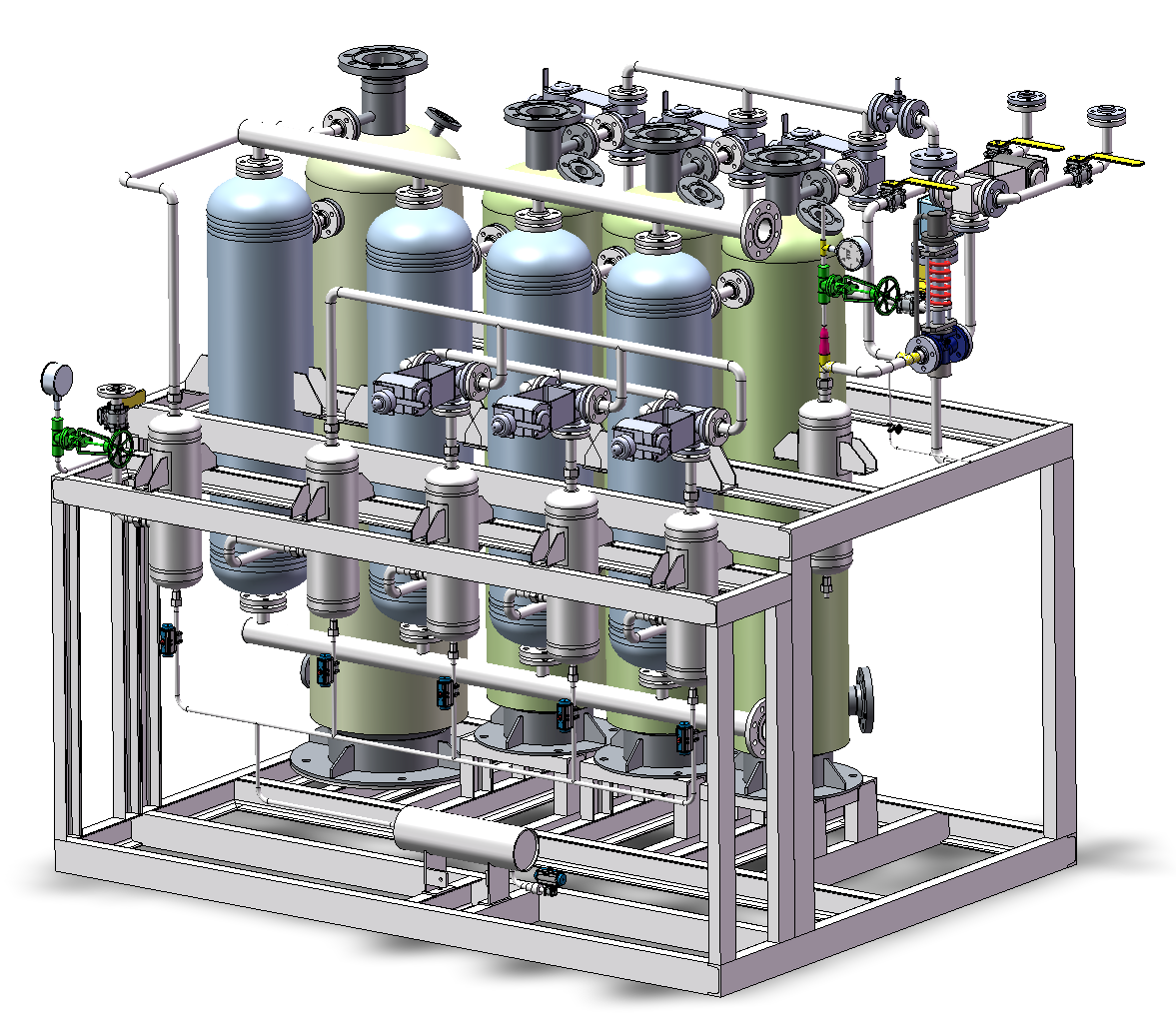

QINGY alkaline electrolysis equipment is designed to integrate seamlessly with various hydrogen storage solutions, ensuring renewable energy can be deployed when and where it’s needed:

– **High-Pressure Hydrogen Production**: Our systems can produce hydrogen at pressures up to 30 bar, ideal for direct compression and storage in high-pressure tanks for short-to-medium term needs

– **Integration with Liquid Hydrogen Facilities**: For seasonal storage requirements, our electrolyzers provide a consistent supply of high-purity hydrogen for liquefaction

– **Chemical Storage Compatibility**: The high-purity hydrogen from QINGY systems is perfect for synthesis into ammonia or methanol—hydrogen carriers that enable long-distance transport and long-term storage

– **Grid Injection Readiness**: Our hydrogen meets the purity standards required for blending with natural gas grids, creating another storage pathway while decarbonizing existing infrastructure

Renewable energy projects have specific requirements that QINGY alkaline electrolysis systems address:

– **Remote Monitoring Capabilities**: Advanced telemetry allows operators to monitor and control systems from anywhere, critical for installations in remote locations

– **Extreme Environment Design**: Systems are engineered to withstand the harsh conditions of desert solar farms or offshore wind installations

– **Low Maintenance Requirements**: Designed for continuous operation with minimal downtime, maximizing renewable energy capture

– **Customizable Configurations**: Tailored solutions to match specific project footprints, power inputs, and hydrogen output requirements

– **Grid Code Compliance**: Systems meet the technical requirements for grid connection, including voltage and frequency control capabilities

Beyond technical advantages, QINGY systems deliver compelling economic benefits:

– **Reduced Curtailment Losses**: Capturing otherwise wasted renewable energy increases project revenue

– **Energy Cost Optimization**: Ability to leverage off-peak renewable energy for hydrogen production when electricity costs are lowest

– **Revenue Diversification**: Hydrogen production creates additional income streams for renewable energy projects

– **Long Equipment Lifespan**: Our electrolyzers are built for 20+ years of operation, ensuring long-term return on investment

– **Incentive Eligibility**: Qualifies for various government incentives for clean hydrogen production in many regions

As the world moves toward a carbon-neutral future, QINGY alkaline electrolysis hydrogen equipment has become more than just a technological solution—it’s a strategic enabler of the renewable energy transition. Our systems empower energy providers to maximize the value of their renewable assets while creating a reliable, dispatchable source of clean energy.

By integrating QINGY alkaline electrolysis equipment into your renewable energy project, you’re not just investing in hydrogen production—you’re building a flexible, future-proof energy system that can adapt to the evolving needs of the grid and society. Contact us today to discover how our tailored solutions can help you unlock the full potential of your renewable energy assets through hydrogen production and storage.

The future of renewable energy is hydrogen-enabled, and QINGY is leading the way with innovative, reliable alkaline electrolysis technology.