Chlorine is an essential chemical used in water treatment, disinfection, and various industrial processes. The brine electrolysis chlorine generation system is an innovative technology that produces chlorine on-site, eliminating the need for hazardous chemical transportation and storage. This article will explain how this system works, its key components, and the benefits it offers.

## Understanding the Basics of Brine Electrolysis

The brine electrolysis chlorine generation system uses a simple yet effective process to produce chlorine gas from a saltwater solution. The system works on the principle of electrolysis, where an electric current is passed through a brine solution (sodium chloride dissolved in water) to break down the chemical components.

The core chemical reaction in the electrolysis process is:

2NaCl + 2H₂O → 2NaOH + H₂ + Cl₂

This reaction produces three valuable products: sodium hydroxide (caustic soda), hydrogen gas, and chlorine gas. Each of these products has important industrial applications.

## Key Components of the System

A typical brine electrolysis chlorine generation system consists of several essential components:

1. **Brine Preparation Unit**: This section prepares the saltwater solution by dissolving solid salt in water to create a concentrated brine solution.

2. **Electrolyzer**: The heart of the system, where the actual electrolysis takes place. It contains electrodes and membranes that facilitate the chemical reactions.

3. **Power Supply**: Provides the necessary electrical current to drive the electrolysis process.

4. **Product Separation and Purification System**: Separates and purifies the generated chlorine gas, hydrogen gas, and sodium hydroxide solution.

5. **Control and Monitoring System**: Regulates the entire process, ensuring optimal performance and safety.

## The Electrolysis Process Step-by-Step

Let’s take a closer look at how the brine electrolysis chlorine generation system works from start to finish:

1. **Brine Preparation**: Solid salt (sodium chloride) is dissolved in water to create a concentrated brine solution, typically with a concentration of about 30% by weight.

2. **Purification**: The brine solution undergoes a purification process to remove impurities that could affect the electrolysis process or contaminate the final products.

3. **Electrolysis**: The purified brine solution is pumped into the electrolyzer, where an electric current is applied through electrodes. This causes the water molecules to split into hydrogen ions (H⁺) and hydroxide ions (OH⁻).

4. **Ion Migration**: Under the influence of the electric field, positive sodium ions (Na⁺) migrate toward the negative electrode (cathode), while negative chloride ions (Cl⁻) migrate toward the positive electrode (anode).

5. **Chemical Reactions**:

– At the anode: Chloride ions lose electrons and form chlorine gas (Cl₂).

– At the cathode: Water molecules gain electrons and form hydrogen gas (H₂) and hydroxide ions (OH⁻).

6. **Product Collection**: The generated chlorine gas, hydrogen gas, and sodium hydroxide solution are collected separately. The chlorine gas is typically cooled, dried, and compressed for storage or immediate use.

## Types of Electrolyzers

There are several types of electrolyzers used in brine electrolysis chlorine generation systems, each with its own design and operating characteristics:

1. **Diaphragm Cell Technology**: Uses a porous diaphragm to separate the anode and cathode compartments, allowing ions to pass through while preventing the mixing of products.

2. **Membrane Cell Technology**: Utilizes an ion-exchange membrane that selectively allows only certain ions to pass through, resulting in higher purity products and greater energy efficiency.

3. **Mercury Cell Technology**: Involves a mercury cathode that forms an amalgam with sodium ions, which is then reacted with water to produce sodium hydroxide and hydrogen gas. This technology is being phased out in many regions due to environmental concerns.

## Advantages of Brine Electrolysis Chlorine Generation

The brine electrolysis chlorine generation system offers several significant advantages over traditional chlorine production methods:

– **On-Site Production**: Eliminates the need for transporting and storing large quantities of hazardous chlorine gas.

– **Safety**: Reduces the risks associated with handling and storing chlorine, which is classified as a toxic and corrosive substance.

– **Cost-Effectiveness**: Producing chlorine on-site can be more economical than purchasing it from external suppliers, especially for large-scale users.

– **Environmental Benefits**: The process produces fewer emissions compared to other chlorine production methods, and the byproducts (hydrogen and sodium hydroxide) can often be reused or sold.

– **Consistent Quality**: The system can be precisely controlled to produce chlorine of consistent quality, which is crucial for applications like water treatment.

## Applications of Generated Chlorine

The chlorine produced by brine electrolysis systems has a wide range of applications:

– **Water Treatment**: Used for disinfecting drinking water, swimming pools, and wastewater.

– **Chemical Manufacturing**: A key ingredient in the production of PVC, solvents, pesticides, and other chemicals.

– **Paper and Pulp Industry**: Used for bleaching paper products.

– **Textile Industry**: Employed in bleaching and dyeing processes.

– **Food Processing**: Used for sanitizing equipment and surfaces in food production facilities.

## Safety Considerations

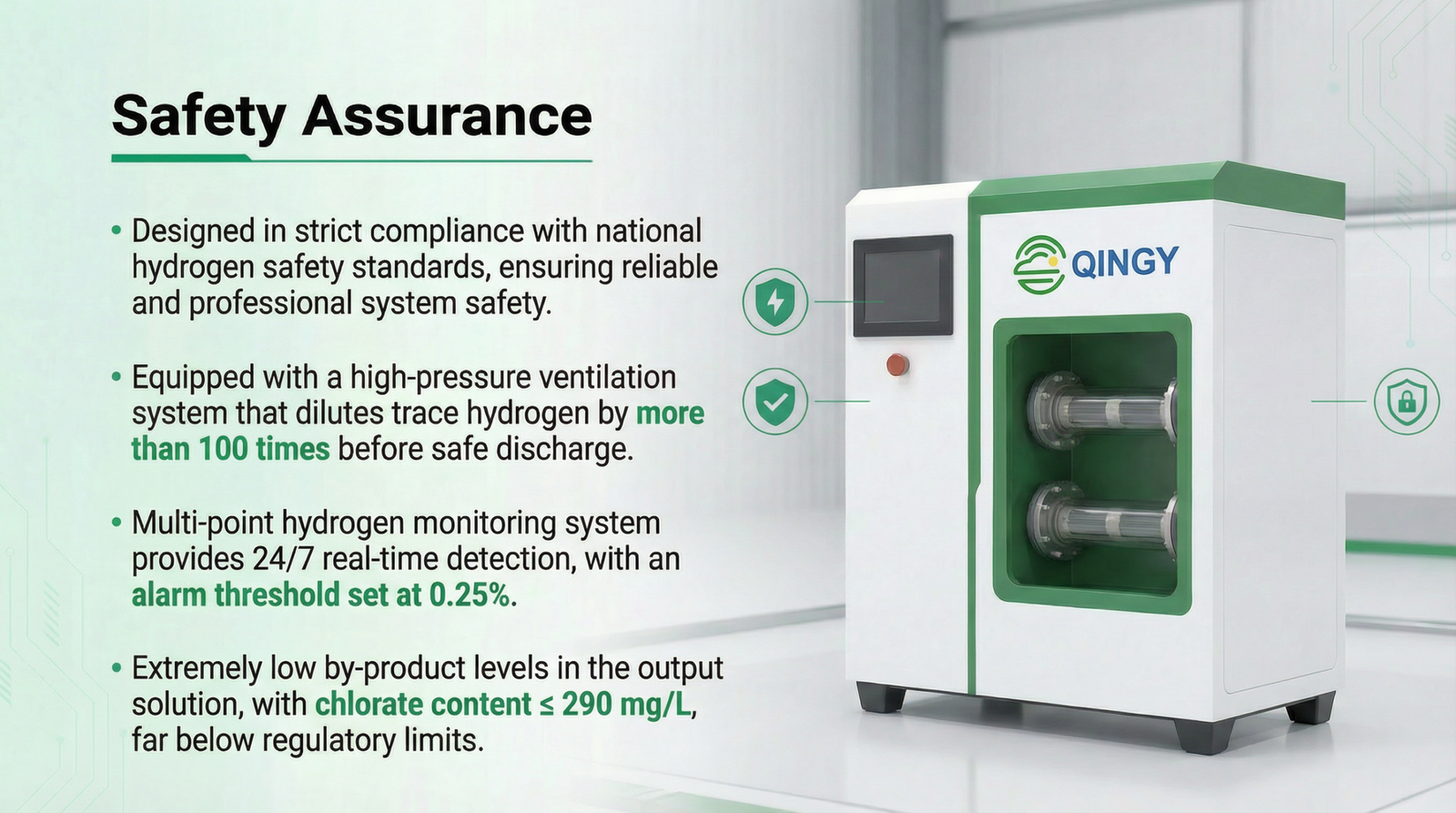

While the brine electrolysis chlorine generation system is generally safe when properly operated, there are important safety considerations:

– **Chlorine Gas Handling**: Chlorine gas is toxic and requires careful handling and monitoring.

– **Hydrogen Gas Management**: Hydrogen gas is highly flammable and must be properly vented or collected to prevent explosion risks.

– **Electrical Safety**: The system operates with high electrical currents, requiring appropriate safety measures to prevent electric shock.

– **Corrosion Protection**: The system components must be made of materials resistant to the corrosive nature of the brine solution and generated products.

## Conclusion

The brine electrolysis chlorine generation system represents a significant advancement in chlorine production technology. By understanding how this system works, industries can make informed decisions about implementing this technology to meet their chlorine needs safely, efficiently, and cost-effectively.

As environmental regulations become more stringent and safety concerns continue to grow, the adoption of brine electrolysis chlorine generation systems is likely to increase across various industries. This technology not only provides a reliable source of chlorine but also contributes to safer working environments and more sustainable industrial practices.

If your organization requires a consistent supply of chlorine for water treatment, chemical manufacturing, or other applications, considering a brine electrolysis chlorine generation system could be a strategic investment that delivers long-term benefits in terms of safety, cost savings, and environmental responsibility.

Learn more about our sodium hypochlorite generator and high concentration sodium hypochlorite generator for industrial disinfection applications.