In an age where environmental responsibility meets operational efficiency, the sodium hypochlorite generator has emerged as a transformative technology for businesses requiring reliable disinfection solutions. This innovative system produces sodium hypochlorite—the active ingredient in household bleach—on-site using only salt, water, and electricity. Whether you manage a water treatment facility, operate a food processing plant, or maintain a public swimming pool, a sodium hypochlorite generator offers a safer, more cost-effective alternative to traditional chemical procurement methods.

The Science of On-Site Sodium Hypochlorite Production

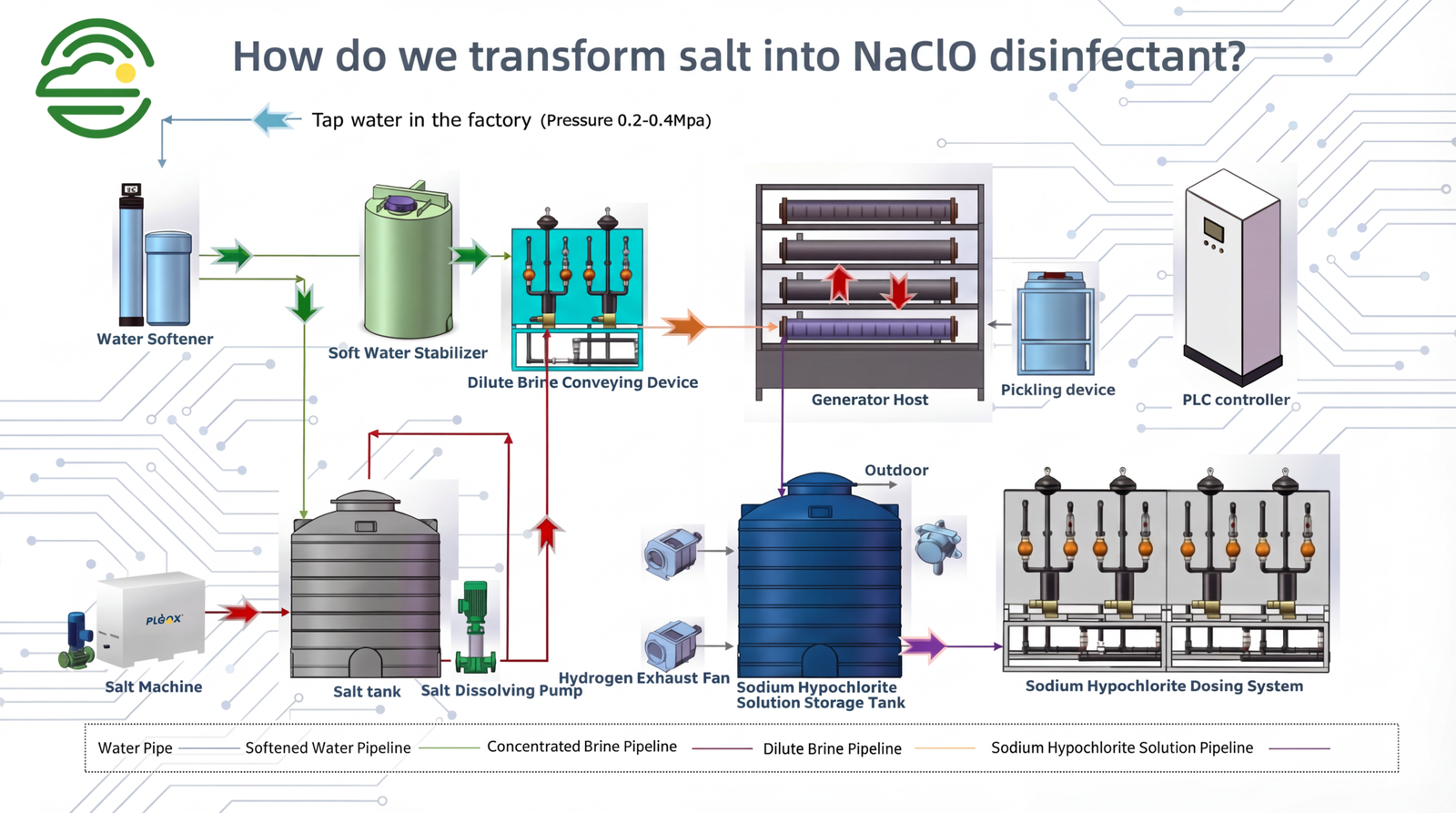

The sodium hypochlorite generator operates on the principle of electrolysis, a process that uses electricity to drive a chemical reaction. Here’s how it works:

- Brine Preparation: The system first creates a saltwater solution by dissolving sodium chloride (NaCl) in water.

- Electrolytic Process: This brine solution passes through an electrolytic cell where an electric current separates the sodium and chloride ions.

- Chemical Transformation: The electrolysis process produces sodium hypochlorite (NaOCl), hydrogen gas, and sodium hydroxide.

- Solution Collection: The resulting solution contains approximately 0.8-1.2% sodium hypochlorite, ready for immediate use.

The entire process is automated and monitored, ensuring consistent production of high-quality disinfectant without manual intervention.

Key Advantages of Sodium Hypochlorite Generators

Investing in a sodium hypochlorite generator offers numerous benefits over traditional chemical purchasing methods:

- Cost Reduction: On-site production can cut chemical costs by 30-50% compared to purchasing pre-made solutions.

- Enhanced Safety: Eliminate risks associated with transporting and storing large quantities of concentrated chemicals.

- Improved Quality Control: Maintain precise concentration levels for different applications, ensuring optimal disinfection performance.

- Environmental Benefits: Reduce plastic waste from chemical containers and minimize carbon emissions from transportation.

- Operational Flexibility: Adjust production levels based on demand, avoiding overstocking or shortages.

- Regulatory Compliance: Simplify compliance with increasingly stringent chemical handling regulations.

Applications Across Diverse Industries

Sodium hypochlorite generators find applications in various sectors where reliable disinfection is essential:

- Water Treatment: Municipal water treatment plants use sodium hypochlorite for primary disinfection and biofilm control.

- Food Processing: Sanitizing equipment, surfaces, and process water in food and beverage production facilities.

- Healthcare Facilities: Disinfecting medical equipment, surfaces, and water systems in hospitals and clinics.

- Aquatic Facilities: Maintaining water quality in swimming pools, spas, and water parks.

- Agriculture: Sanitizing irrigation water and equipment in farming operations.

- Hospitality: Ensuring clean water and surfaces in hotels, resorts, and cruise ships.

Choosing the Right Sodium Hypochlorite Generator

When selecting a sodium hypochlorite generator, consider these important factors:

- Production Capacity: Determine your daily sodium hypochlorite requirements to select a system that matches your operational needs.

- Quality Components: Look for systems with durable, corrosion-resistant materials like titanium electrodes and high-quality membranes.

- Automation Features: Advanced systems offer automated monitoring and adjustment capabilities for optimal performance.

- Energy Efficiency: Select models with high energy efficiency ratings to minimize operational costs.

- Scalability: Consider whether the system can expand with your business as needs grow.

- Technical Support: Ensure the manufacturer provides comprehensive installation, training, and maintenance support.

Maintenance and Long-Term Performance

Proper maintenance is essential for maximizing the lifespan and efficiency of your sodium hypochlorite generator:

- Regular Inspections: Schedule routine system checks to identify potential issues before they impact performance.

- Electrode Cleaning: Follow manufacturer recommendations for cleaning electrodes to maintain optimal electrolysis efficiency.

- Water Quality Management: Monitor incoming water quality to prevent scaling and mineral buildup in the system.

- Component Replacement: Replace consumable parts according to the manufacturer’s schedule to maintain performance.

- Operator Training: Ensure staff members receive proper training on system operation and safety protocols.

Conclusion: The Future of Disinfection is On-Site

A sodium hypochlorite generator represents a strategic investment in operational efficiency, safety, and sustainability. By producing your own disinfectant on-site, you gain control over your chemical supply chain while reducing costs and improving safety.

As businesses increasingly prioritize sustainability and cost control, sodium hypochlorite generators will become even more integral to modern disinfection strategies. The technology continues to evolve, with newer models offering enhanced automation, energy efficiency, and remote monitoring capabilities.

Whether you’re looking to upgrade your current chemical management system or implement a new disinfection solution, a sodium hypochlorite generator offers a proven, cost-effective approach. With proper selection and maintenance, these systems can provide reliable service for 10-15 years, delivering a substantial return on investment.

Take the first step toward transforming your disinfection processes. Contact a sodium hypochlorite generator specialist today to evaluate your specific needs and discover how on-site generation can benefit your operations.

Advantages of Using an On-Site Sodium Hypochlorite Generator for Disinfection

– Reduced chemical transportation and storage risks

– Improved operational safety compared with chlorine gas

– More stable disinfectant concentration for consistent disinfection performance

– Lower long-term operating cost for industrial and municipal facilities

Call to Action

Contact Qingyau to discuss your water flow, chlorine dosage targets, and site conditions. Our engineers can recommend the right sodium hypochlorite generator configuration and capacity for your project.

Learn more about our sodium hypochlorite generator and high concentration sodium hypochlorite generator for industrial disinfection applications.